- 1

- 2

|

信息詳情

當前位置:

首頁(yè)>

信息詳情

Reasons and countermeasures for unqualified aluminum stamping workpiece

專(zhuān)欄:Industry Information

發(fā)布日期:2018-04-09

閱讀量:948

作者:

收藏:

The surface quality of the coil, sheet and mold will affect the quality of the final stamped parts.(10) Poor material beyond the rules;(2) Mold: Iron powder is generated when the drawbead is burned;

Stamping is the first of the four major processes, and its importance can be imagined. There are many reasons for the poor stamping parts. The surface quality of the coil, sheet and mold will affect the quality of the final stamped parts. The operation in the stamping process and the loading and unloading of the station equipment may also damage the surface quality of the parts. Therefore, the details should be fully considered in every part of the entire manufacturing process to avoid quality problems and affect the final product appearance.

1, coil material Common defects in coil materials mainly include the following: (1) foreign matter is mixed in or on the surface of the steel sheet; (2) The foreign matter is peeled off, and the coil is in the same state as the scar; (3) The corner of the coil is damaged; (4) The corners (20 to 30 mm) are deformed or crumpled due to uneven stress; (5) scratches (on the surface of the roller or caused by foreign matter); (6) caused by roller slip; (7) Irregular edge damage; (8) After the foreign matter enters, the bulge is pressed out on the back of the coil (the foreign matter disappears and disappears); (9) Roll marks (caused by foreign matter adhering to the roller); (10) Poor material beyond the rules; (11) Foreign matter causes obvious groove marks on the surface depth. According to practical experience, among the above, items 5, 8, and 9 are the bad performance or cause of the most frequently produced parts.

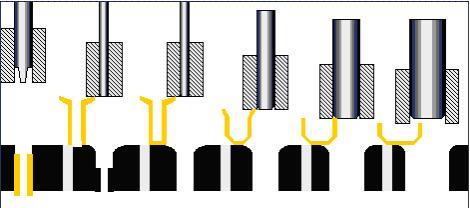

2, sheet material The common occurrences of sheets are as follows: (1) burr: burr is generated in the lower part of the section of the steel plate. When the burr height is 0.2mm or more, the iron powder generated here will damage the mold and produce convex and concave; (2) Roller printing: causing foreign matter to adhere to the cleaning roller or the feeding roller (occurring at a fixed pitch); Figure 2 Roller print on the sheet (3) Sliding print: occurs when the roller slides, when it stops suddenly or accelerates; (4) Broken or edge wrinkles of the coil: wrinkles occurring in the gap between the guide rolls of the unwinding line or the guide rolls on the mold, due to unbalanced feeding of the coil; (5) Concavities and Concavities: Foreign matter (iron filings, dust) mixed in the unwinding line causes bumps and depressions. 3, mold (parts) Common problems that may arise with mold parts are: (1) Wrinkles: wrinkles on the edge or r part due to poor adjustment of the press slider, low precision of the press, improper adjustment of the air cushion pressure, large punch or r-port; (2) Line offset: When the part is formed, the part that first contacts the mold is squeezed and forms a line; (3) Adhesion, scratching: defects occurring on the surface of the part or mold due to the friction of the material with the punch or the die; (4) Concavities and concaves: foreign matter (iron filings, rubber, dust) mixed in the unwinding line causes the convex and concave; (5) Zigzag and strain: due to uneven stress, poor matching of drawbeads or poor control of the slider of the press, the n-angle or embossed parts of the workpiece are tortuous and strained; (6) Burr: mainly occurs in the shearing die and the blanking die, and the gap between the cutting edges may generate burrs when it is large or small. 4, stamping parts convex and concave The most common problem with the surface of parts in stamping production is the problem of unevenness, which is mostly caused by the adhesion of dust or iron filings on the surface of the material or the mold, which reduces the surface quality of the part and also reduces the productivity. Cause of bump (1) Material: Iron powder is produced when the coil material is cut off; after the coil material is cut off, the section is left with burrs; the sheet material is stored or transported with dirt. (2) Mold: Iron powder is generated when the drawbead is burned; the position of the vent hole of the drawing die is unreasonable to cause the convexity and concave of the final part; the shearing die causes (mainly the waste cutting edge) to be convex and concave. (3) Others: If the robot's speed setting is unreasonable, it will cause collision when it enters the inside of the mold, resulting in poor final parts. Corresponding countermeasures to reduce unevenness (1) Check the section When cutting the coil, the wear and tear of the cutting die will cause a lot of tiny iron powder to adhere to the cutting edge. Therefore, before the stamping production, the double cross section must be inspected in the material area or the press line, and the sheet material should be cleaned to remove the burr. (2) Inspection of sheet cleaning device It is also necessary to inspect and trim the cleaning device at the same time before stamping to make it more efficient to clean the sheet. It is also necessary to pay attention to the roller gap and the quality of the cleaning oil. The specific method is to apply a red paint on a steel plate and then pass it through the cleaning device, and then check the result state of the red paint being removed. If the removal rate is not up to standard, the cleaning device must be inspected and trimmed. When the cleaning oil is missing, it must be added in time. (3) Inspection and correction of the drawing die The drawing die needs to be regularly inspected and maintained to reduce the occurrence of bumps and to maintain a steady state. The usual practice is to use a sample to check the bond scratches of the binder ring and the machined surface (concave fillet, punch fillet). (4) Inspection and correction of shearing die The reason why the convexity and concave appear after the shearing process is that iron powder is generated during the shearing process, so it is necessary to observe the iron powder before the punching to avoid the occurrence of the unevenness. (5) Appropriate robot speed For semi-automatic drawing die production, when the drawing punch is in the lower die position and the robot speed is fast, the burr will fall on the upper part of the punch, causing the convex and concave. In order to avoid this problem, we can make the discharge test of the workpiece before production, and reasonably set the speed and discharge angle of the robot so that it does not touch the workpiece and the lower mold. |